Teknụzụ evaporation na crystallization

Molasses mmanya na-emebi mmiri mmiri nwere mmetụta evaporation ngwaọrụ

Nchịkọta

Isi mmalite, njirimara na mmebi nke molasses mmanya na-abaghị uru

Mmiri na-ekpofu mmanya Molasses bụ nnukwu uche na mmiri mkpofu ahịhịa dị elu nke a na-ewepụta na ụlọ ọrụ mmanya nke ụlọ ọrụ shuga iji mepụta mmanya na-aba n'anya mgbe agbachara mmiri nke molasses. Ọ bara ụba na protein na ihe ndị ọzọ na-edozi ahụ, ma nweekwa salts inorganic dị ka Ca na Mg na mkpokọta dị elu. SO2 na ndị ọzọ. Dị ka ọ na-adịkarị, pH nke mmiri mkpofu mmanya bụ 4.0-4.8, COD bụ 100,000-130,000 mg/1, BOD bụ 57-67,000 mgSs, 10.8-82.4 mg/1. Na mgbakwunye, ọtụtụ n'ime ụdị mmiri mkpofu a bụ acidic, na agba dị oke elu, agba aja aja-oji, ọkachasị gụnyere agba caramel, agba phenolic, agba Maillard na ihe ndị ọzọ. Ebe ọ bụ na mmiri mmiri na-ekpofu ihe nwere ihe dị ka 10% siri ike, ntinye uche dị ala na enweghị ike iji ya. Ọ bụrụ na a na-agbanye ya ozugbo n'ime osimiri na ala ubi na-enweghị ọgwụgwọ, ọ ga-emerụ àgwà mmiri na gburugburu ebe obibi nke ọma, ma ọ bụ mee ka ala na-eme ka acid na-agbakọta, na-eto eto nke ọrịa ihe ọkụkụ. Otu esi eme ihe na iji mmiri mkpofu mmanya molasses bụ nnukwu nsogbu gburugburu ebe obibi chere ụlọ ọrụ shuga ihu.

Mmiri mmanya na-egbu egbu nke Molasses na-emebi nke ukwuu ma nwee chroma dị elu, nke siri ike iwepụ site na usoro biochemical. Mkpokọta ọkụ ma ọ bụ fatịlaịza mmiri na-arụ ọrụ nke ọma bụ atụmatụ ọgwụgwọ kachasị mma ugbu a.

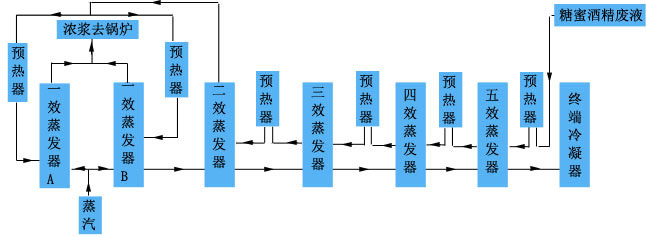

Ngwa ahụ na-anakwere usoro mgbasa ozi na-amanye nke ọma ise, yana uzuoku juputara dị ka isi iyi ọkụ, otu mmetụta kpo oku na ọrụ mmetụta ise. Molasses mmanya na-emebi mmiri nke nwere ntinye nke 5 ruo 6% na-etinye ma na-ekupụ ya, a na-ezigakwa slurry nwere ntinye nke ≥ 60% na igwe ọkụ ọkụ maka ọkụ, ọkụ na-emepụta na-ejukwa uzuoku maka ngwaọrụ ahụ. Wepu mmiri a kpụkọrọ akpụkọ azụ na ngalaba gara aga maka mmiri dilution.

Nke abụọ, usoro nhazi usoro

Nke atọ, njirimara usoro

1. Tọọ evaporator mapụtara iji kpochapụ ihe ahụ, nke nwere ike ịghọta na-adịghị akwụsị ihicha ma hụ na mmepụta na-aga n'ihu.

2. Ngwaọrụ na-anabata njikwa mmemme akpaka iji chekwaa ụgwọ ọrụ.

3. Ịrụ ọrụ nhazi dị elu na arụ ọrụ kwụsiri ike.

4. Site n'iji nnukwu slurry laghachi na ọkụ ọkụ, molasses nwere ike ịmịpụta mmanya na-enweghị ịgbakwunye mmanụ.

5. A na-edozi evaporator mapụtara maka mmetụta nkwụsị, nke nwere ike ịghọta na-adịghị akwụsị ihicha ma hụ na mmepụta na-aga n'ihu.

6. Enwere ike imepụta mmanya na-aba n'anya site na molasses na-agbakwunyeghị mmanụ ọkụ site na nnukwu slurry na igwe ọkụ maka ijigharị na molasses.